27

04/2025

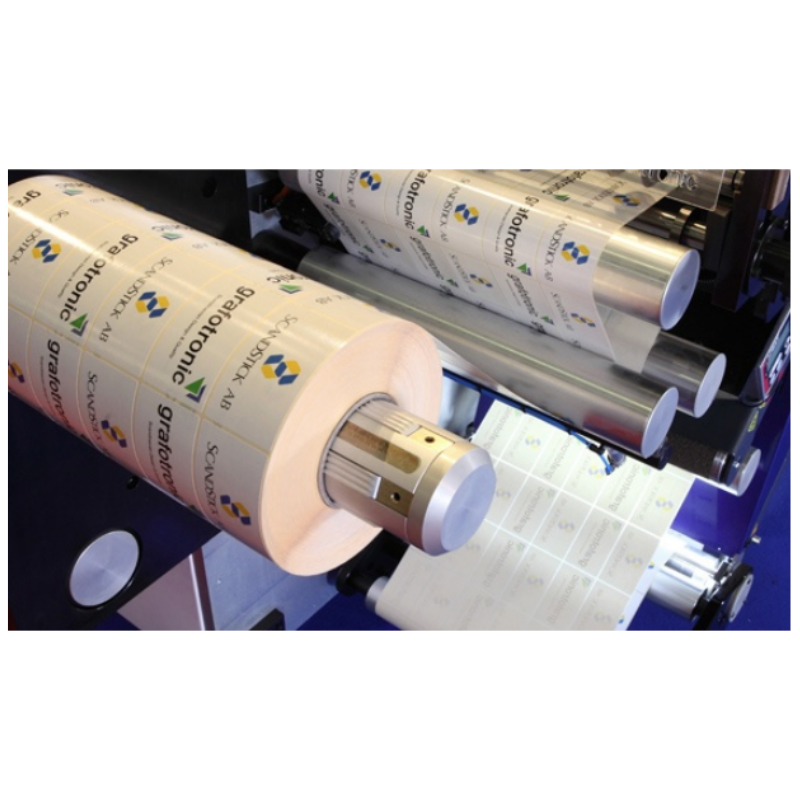

Key Components and Technical Evolution of Flexographic Printing Machines

Flexographic printing machines have undergone significant advancements, evolving from traditional mechanical systems to fully automated, intelligent equipment. This progress is driven by continuous improvements in several key components. Understanding them helps users select the right machine for their needs.

Flexographic printing machines have undergone significant advancements, evolving from traditional mechanical systems to fully automated, intelligent equipment. This progress is driven by continuous improvements in several key components. Understanding them helps users select the right machine for their needs.

1. Key Components Overview

a. Plate Cylinder

Carries the flexible printing plates and plays a central role in image transfer. Modern plate cylinders allow fast replacement to enhance productivity.

b. Anilox Roller

Transfers ink evenly to the plate. Its precision and adjustable cell count make it critical for achieving high-quality print results.

c. Printing Unit

Each unit handles a color. Satellite-type flexo presses use a central impression drum to ensure excellent register accuracy and print stability.

d. Drying Unit

Uses hot air or UV systems to fully dry ink during high-speed operations, preventing smearing or offset.

e. Auto Control System

Includes tension control, registration control, and remote diagnostics. It significantly reduces manual errors and labor requirements.

2. Trends in Technology

• Smart features: Integration of sensors and remote monitoring systems for enhanced visualization and ease of operation.

• Eco-efficiency: New drying technologies reduce energy consumption; water-based inks and solvent-free lamination are on the rise.

• Modular design: Enables easier maintenance, upgrades, and customization, improving the machine’s flexibility and lifecycle.

As the industry advances toward a more efficient, green, and intelligent future, investing in the right flexo technology can yield long-term benefits in quality and operational efficiency.